kenworth t800 wiring diagram pdf

Kenworth T800 Wiring Diagram PDF⁚ A Comprehensive Guide

The Kenworth T800 is a popular heavy-duty truck known for its reliability and performance. Understanding the electrical system of this truck is crucial for both maintenance and troubleshooting. A Kenworth T800 wiring diagram PDF can be an invaluable resource for anyone working on this vehicle. This guide will provide a comprehensive overview of Kenworth T800 wiring diagrams, including their purpose, resources, and how to utilize them effectively.

Introduction

Kenworth T800 wiring diagrams are essential tools for anyone involved in maintaining, repairing, or modifying these trucks. They provide a visual representation of the electrical system, showing the connections between components, wire colors, and circuit pathways. These diagrams are crucial for understanding the flow of electricity throughout the truck, allowing technicians to identify potential problems, troubleshoot electrical issues, and perform repairs efficiently.

A Kenworth T800 wiring diagram PDF is a digital version of the wiring diagram, offering several advantages over traditional paper copies. These PDFs are easily accessible, searchable, and printable, making them convenient for reference and use. They are also readily available online, often for free download, making them a valuable resource for both professional mechanics and DIY enthusiasts.

This guide will delve into the world of Kenworth T800 wiring diagrams, exploring their various uses, common resources, and helpful tips for navigating their complexities. By the end, you’ll have a better understanding of how these diagrams work and how to utilize them effectively to maintain your Kenworth T800’s electrical system.

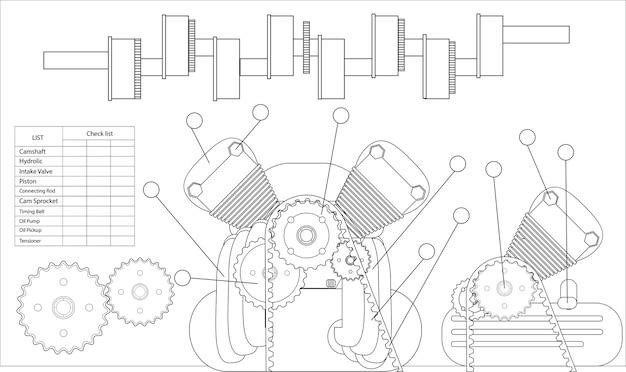

Engine Performance Wiring Diagram

The engine performance wiring diagram focuses specifically on the electrical circuits related to the engine’s operation. This diagram is crucial for understanding how the engine control module (ECM) interacts with various sensors, actuators, and other components to regulate fuel injection, ignition timing, and other critical functions. It details the connections between the ECM, sensors such as the crankshaft position sensor, camshaft position sensor, and oxygen sensors, as well as actuators like fuel injectors and the turbocharger control system.

Understanding the engine performance wiring diagram is essential for diagnosing engine-related problems. By tracing the electrical pathways, technicians can pinpoint faulty sensors, wiring issues, or malfunctioning actuators that could be affecting engine performance. This diagram also helps in identifying potential issues with the ECM itself, which plays a crucial role in regulating engine functions.

For example, if a Kenworth T800 experiences a rough idle or reduced power, the engine performance wiring diagram can help identify if the problem lies in a faulty oxygen sensor, a malfunctioning fuel injector, or a communication issue between the ECM and a specific component. This diagram is a valuable resource for both troubleshooting and repair, ensuring optimal engine performance.

Kenworth T800 Wiring Diagram Resources

Finding reliable Kenworth T800 wiring diagrams can be a bit of a challenge, but there are several resources available. The most comprehensive source is typically the official Kenworth service manuals. These manuals are available through authorized Kenworth dealerships or online retailers specializing in automotive repair manuals. The manuals contain detailed wiring diagrams for various model years, including specific configurations and engine options.

Alternatively, you can explore online forums and communities dedicated to Kenworth trucks. Many enthusiasts and mechanics share their knowledge and resources, including wiring diagrams, troubleshooting tips, and repair guides. Websites like Kenworth’s official website and forums like “The Kenworth Truck Forum” can be valuable sources of information.

Keep in mind that online resources may vary in accuracy and completeness. Always verify information from multiple sources and consult official service manuals whenever possible. Additionally, using a reputable online repair manual subscription service can provide access to a vast library of wiring diagrams for various vehicle models.

Cab Power Feed Harness

The cab power feed harness is a critical component of the Kenworth T800 electrical system, responsible for delivering power to the cab’s various electrical components. Understanding the wiring diagram for this harness is essential for diagnosing and repairing electrical issues within the cab. The harness typically includes wires for lights, gauges, switches, accessories, and other electrical systems.

A wiring diagram for the cab power feed harness will usually depict the connections between the fuse box, battery, and various components within the cab. It will show the wire gauge, color coding, and location of each wire. This information is crucial for tracing electrical circuits, identifying faulty wiring, and ensuring proper connections.

When working with the cab power feed harness, it is essential to follow safety precautions and consult the relevant wiring diagram to avoid damage to the electrical system. Understanding the function of each wire and its connection points is crucial for maintaining the integrity of the truck’s electrical system.

Kenworth T800 Electrical System Updates

Kenworth has continuously updated the electrical systems of its T800 trucks over the years, incorporating new technologies and features. These updates can influence the wiring diagrams and require careful consideration when diagnosing and repairing electrical issues. When working with a Kenworth T800, it is crucial to determine the specific year and model of the truck to access the correct wiring diagram.

For instance, Kenworth introduced a new electrical wire numbering system in 2007, which can be confusing for those unfamiliar with the older system. Additionally, the addition of new features like advanced driver-assistance systems (ADAS) can significantly alter the electrical system’s complexity. It is crucial to consult the latest wiring diagrams available for the specific year and model of the T800 to ensure accurate troubleshooting and repair.

Staying up-to-date with Kenworth’s electrical system updates is essential for technicians and mechanics. Accessing the latest wiring diagrams and resources from Kenworth or reputable third-party sources can help avoid misdiagnosis and ensure proper repair procedures.

Kenworth T800 Body Builders Manual

The Kenworth T800 Body Builders Manual is a crucial resource for anyone involved in modifying or adding components to a Kenworth T800 truck. This manual provides detailed information on the truck’s chassis, electrical systems, and mounting points, specifically designed to assist body builders in integrating their custom structures and equipment seamlessly.

The manual includes comprehensive wiring diagrams that highlight the specific connections and points necessary for integrating external components. It also provides guidance on proper installation procedures, ensuring that the modifications comply with safety regulations and maintain the truck’s structural integrity. Accessing the Body Builders Manual is essential for avoiding potential electrical issues, ensuring the functionality of added equipment, and guaranteeing the overall safety of the modified vehicle.

While the manual is primarily intended for professional body builders, it can also be a valuable resource for individuals undertaking minor modifications or repairs. Understanding the wiring diagrams and installation procedures outlined in this manual can contribute to a smoother and more successful customization process.

Kenworth T800 Wiring Diagram for Specific Components

Kenworth T800 wiring diagrams often provide detailed information for specific components within the truck’s electrical system. These diagrams can be invaluable when troubleshooting issues with particular systems, such as the engine performance, cab power feed harness, or even individual accessories. They often include a clear visual representation of the wiring pathways, connectors, and fuse locations for a specific component.

For example, a wiring diagram specific to the engine performance might illustrate the connections between the engine control module (ECM), sensors, actuators, and other related components. Similarly, a diagram for the cab power feed harness would detail the wiring that supplies power to the cab’s lights, gauges, and other electrical systems. These component-specific diagrams streamline troubleshooting by focusing on the relevant circuits and eliminating the need to navigate through a complex overall wiring diagram.

When working on a specific system, having the appropriate component-specific wiring diagram can save time and effort. It allows for a targeted approach to identifying potential problems, ensuring proper connections, and ultimately ensuring the correct operation of the component.

Troubleshooting Kenworth T800 Electrical Issues

A Kenworth T800 wiring diagram is an indispensable tool for diagnosing and resolving electrical issues in these trucks. By providing a visual representation of the wiring paths, connectors, and fuse locations, the diagram simplifies the troubleshooting process. When encountering an electrical problem, the diagram can help pinpoint the affected circuit and isolate the source of the issue.

For instance, if a specific light or gauge is malfunctioning, the diagram can guide you to the corresponding wiring path, fuse, and connector. By examining the diagram, you can determine if the problem lies in a broken wire, a blown fuse, a faulty connector, or a more complex issue within the electrical system. Understanding the wiring layout allows you to trace the electrical flow and systematically check for any potential points of failure.

The use of a wiring diagram can significantly reduce the time and effort required to identify and address electrical problems. It provides a clear roadmap for tracing circuits, testing components, and ultimately restoring proper electrical function to the truck.

Safety Precautions When Working with Electrical Systems

Working with electrical systems in a Kenworth T800 requires utmost caution and adherence to safety procedures. The high voltage and potential for electrical shock pose serious risks. Before starting any electrical work, always ensure the truck’s battery is disconnected to eliminate the risk of accidental electrocution. This step is crucial, even when working on seemingly simple tasks, as unexpected electrical currents can be hazardous.

Additionally, never attempt to work on live electrical components. Always isolate the circuit before conducting any repairs or modifications. Use insulated tools and protective gear, such as gloves and eye protection, to minimize the risk of electrical shock. If unsure about any procedure, consult a qualified technician or refer to the Kenworth T800 service manual for detailed instructions.

Following these safety precautions is essential for ensuring the safety of yourself and those around you. Working with electrical systems responsibly helps prevent accidents and injuries, allowing you to complete tasks effectively and without compromising your well-being.

In conclusion, a Kenworth T800 wiring diagram PDF serves as a valuable resource for anyone working on the electrical system of this truck. From understanding the basic layout of the system to troubleshooting specific issues, these diagrams provide detailed information and visual representations that simplify complex electrical configurations. By utilizing the available resources and following proper safety precautions, you can effectively navigate the intricacies of the Kenworth T800’s electrical system.

Remember to consult the official Kenworth T800 service manual for comprehensive information and guidance on electrical repairs and modifications. This manual is essential for ensuring proper maintenance and troubleshooting, as well as for adhering to safety standards. By approaching electrical work with knowledge, caution, and the right tools, you can confidently maintain and repair the electrical systems of your Kenworth T800, ensuring its reliable performance and longevity.