flex duct installation guide

Flex Duct Installation Guide⁚ A Comprehensive Overview

This guide provides a complete walkthrough of flexible duct installation, covering planning, material selection, proper techniques, and troubleshooting. Learn best practices for achieving optimal airflow, efficiency, and longevity of your HVAC system. Consult the Air Diffusion Council’s standards for comprehensive guidelines.

Understanding Flex Duct Advantages and Disadvantages

Flexible ductwork offers significant advantages in HVAC installations. Its flexibility allows for easy navigation around obstacles, making it ideal for tight spaces and complex layouts where rigid ductwork would be challenging or impossible to install. This adaptability often translates to reduced installation time and labor costs compared to traditional metal duct systems. The lightweight nature of flexible ducts also simplifies handling and maneuverability during the installation process. Furthermore, the material’s inherent flexibility allows for easier adjustments during installation, accommodating unforeseen circumstances or minor design changes.

However, flexible ductwork also presents some disadvantages. One major concern is the potential for air leakage if not installed and sealed properly. The flexible nature of the material can lead to sagging if inadequate support is provided, restricting airflow and reducing system efficiency. Additionally, flexible ducts are more susceptible to damage from compression or kinking during installation, potentially affecting airflow. The material’s lower durability compared to rigid metal ductwork also means it may require more frequent maintenance or replacement over its lifespan. Lastly, improper installation can lead to increased noise levels compared to well-installed rigid duct systems.

Choosing the Right Flex Duct⁚ Material, Size, and Insulation

Selecting the appropriate flexible duct involves careful consideration of material, size, and insulation. The material choice often depends on the application and environmental conditions. Common materials include aluminum foil, vinyl, and polyethylene. Aluminum foil-faced ducts offer excellent reflectivity, minimizing heat transfer, while vinyl and polyethylene options provide cost-effective solutions for less demanding applications. Proper sizing is crucial for optimal airflow and system efficiency. Undersized ducts restrict airflow, leading to increased pressure drop and reduced system performance. Conversely, oversized ducts can cause uneven air distribution and waste energy. Accurate sizing calculations, often using software like ACCA Manual D or Manual Q, are essential.

Insulation is another critical factor. Insulated flex duct, typically with a minimum R-8 rating, significantly reduces energy loss and condensation, improving system efficiency and preventing moisture-related problems. The type and thickness of insulation should be selected based on climate conditions and duct location. Properly insulated ducts help maintain consistent air temperature, preventing energy waste and potential damage from condensation. Remember to consult manufacturers’ specifications and industry standards (like those from the Air Diffusion Council) for guidance on material selection, sizing, and insulation requirements to ensure a successful and efficient installation.

Essential Tools and Materials for Installation

Before starting your flex duct installation, gather the necessary tools and materials. This ensures a smooth and efficient process. Essential tools include a measuring tape for accurate length determination, a sharp utility knife or shears for clean cuts, and a metal clamp and/or hose clamps for secure connections. A screwdriver may be needed depending on the type of connectors used. For more complex installations, consider using a duct sealant to create airtight connections. Additionally, having a level handy helps ensure proper alignment and prevents sagging. Safety glasses and work gloves are crucial for protecting your eyes and hands during the installation process.

Necessary materials beyond the flex duct itself include connectors (couplers) for joining duct sections, support straps or hangers for secure mounting, and potentially insulation (duct wrap or insulated flex duct) to improve energy efficiency and prevent condensation. If using mastic or sealant, ensure compatibility with the duct material. Remember to check local building codes and manufacturer’s recommendations for specific requirements. Having all the necessary tools and materials readily available minimizes interruptions and ensures a successful installation. Prioritize safety by using appropriate personal protective equipment (PPE) throughout the process.

Planning Your Flex Duct System⁚ Layout and Design

Effective planning is crucial for a successful flex duct installation. Begin by carefully mapping out the ductwork’s route, considering the shortest, most practical path from the HVAC unit to each register or grille. Minimize bends and turns, as these restrict airflow and increase pressure drop. Consult the ACCA Manual D (for residential) or Manual Q (for commercial) for proper sizing calculations based on your system’s requirements. Accurate sizing ensures optimal airflow and prevents performance issues. Before making any cuts or connections, create a detailed diagram illustrating the ductwork’s layout, including the location of all supports, connectors, and terminations. This visual aid simplifies the installation process and facilitates troubleshooting.

Account for any obstructions, such as walls, ceilings, or existing wiring, when planning the ductwork’s route. Flexible duct’s adaptability allows for navigating obstacles, but careful planning minimizes unnecessary bends and ensures sufficient space for proper installation. Consider using longer runs of straight duct where feasible to reduce the number of joints. Remember that each joint is a potential point of leakage. Proper planning streamlines the installation, minimizes material waste, and results in a more efficient and effective HVAC system. Adhering to manufacturer’s guidelines and industry standards is paramount for ensuring a safe and compliant installation.

Proper Measurement and Cutting Techniques

Accurate measurement is paramount to avoid material waste and ensure a proper fit. Before cutting, carefully measure the required length of the flex duct, adding a small amount of extra length to account for any potential adjustments or minor errors. Use a measuring tape to obtain precise measurements. Mark the cutting point clearly with a pencil or marker to ensure a clean, straight cut. For cutting, employ sharp utility shears or a rotary cutter designed for cutting flexible duct materials. Avoid using tools that might crush or damage the duct’s inner core, as this can impede airflow and reduce efficiency. A clean, even cut prevents fraying and ensures a secure connection.

When cutting insulated flex duct, take care to avoid damaging the insulation layer. A sharp blade minimizes the risk of tearing the insulation, which is crucial for maintaining optimal efficiency and preventing condensation. After cutting, inspect the cut end for any irregularities. If necessary, use a fine-grit sandpaper to smooth out any rough edges or burrs. This improves the seal at the connection point. Remember, precise cuts lead to a better fit and fewer leaks, contributing to a more effective and energy-efficient HVAC system. Always refer to the manufacturer’s instructions for specific recommendations on measurement and cutting techniques for your chosen product.

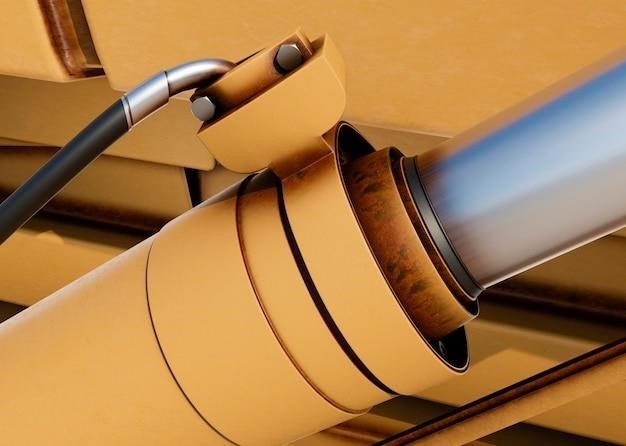

Connecting Flex Duct Sections⁚ Couplers and Clamps

Connecting flex duct sections requires the use of appropriate couplers and clamps to ensure airtight seals and prevent air leaks. Several types of couplers are available, including male and female connectors, designed for seamless joining of duct segments. Select couplers that are compatible with the diameter of your flex duct to guarantee a snug fit. Before connecting, ensure the ends of the duct sections are clean and free of debris or any irregularities that could compromise the seal. Slide one end of a duct section into the coupler, followed by the second section. Ensure both sections are fully seated within the coupler for a secure connection.

Once the coupler is properly positioned, use metal clamps to secure the connection. These clamps should be appropriately sized for the diameter of the flex duct to provide adequate pressure for an airtight seal. Tighten the clamps firmly, but avoid over-tightening, which can potentially crush the duct and restrict airflow. Properly tightened clamps create an airtight seal, preventing air leakage and ensuring efficient operation of your HVAC system. Inspect the connection after tightening the clamps to verify that there are no gaps or leaks. For added security, consider applying a sealant around the coupler and clamp connections to create a completely airtight seal. Following these steps ensures your flex duct system operates efficiently and effectively.

Securing the Ductwork⁚ Support Methods and Spacing

Proper support of flex ductwork is crucial for preventing sagging, kinking, and airflow restrictions. Sagging can cause significant performance issues, reducing efficiency and potentially damaging the duct’s internal structure. The Air Diffusion Council recommends support intervals that prevent excessive sag, generally no more than one-half inch per foot of spacing between supports and a maximum sag of two inches. Utilize appropriate support methods such as straps, hangers, or clips designed specifically for flexible duct. These supports should be evenly spaced along the duct run, with the frequency determined by the duct’s diameter and length.

When installing supports, ensure they don’t compress the duct’s inner core or restrict airflow. Over-tightening supports can damage the duct material and reduce its overall performance; Use a consistent support spacing to maintain uniform tension and prevent uneven sag. Proper support also helps to protect the duct insulation, preventing cold spots and condensation which can lead to mold growth. In areas with high humidity or temperature fluctuations, consider using additional supports to maintain structural integrity. Regular inspection after installation is recommended to ensure all supports remain secure and are not causing any restriction to the airflow. Remember, secure ductwork is essential for optimal system performance and longevity.

Avoiding Common Mistakes⁚ Sagging, Kinking, and Compression

Several common mistakes during flex duct installation can significantly impact performance. Sagging, caused by insufficient support or improper spacing, restricts airflow and can lead to reduced system efficiency. To avoid sagging, follow manufacturer recommendations for support spacing and use appropriately sized and spaced supports. Remember, excessive sag can damage the duct’s inner core, further diminishing performance and potentially causing premature failure. Kinking, often resulting from sharp bends or improper handling, creates similar airflow restrictions. Avoid sharp bends by using gentle curves and appropriately sized transitions. Always handle the duct carefully to prevent kinking during installation.

Compression of the flexible duct’s inner core is another critical concern. Over-tightening clamps or using improperly sized supports can significantly restrict airflow. Ensure that clamps are tightened only enough to create a secure seal without compressing the duct. Properly sized supports distribute the weight of the duct evenly, preventing undue stress on any one point. Careful planning and attention to detail during installation are essential to mitigate these common issues. By following best practices and consulting the Air Diffusion Council’s guidelines, you can avoid these mistakes and ensure your flex duct system operates at peak efficiency. Regular inspection after installation is recommended to identify and address any potential problems early on.

Connecting to Registers and Grilles⁚ Airtight Seals

Creating airtight connections between the flexible duct and registers/grilles is crucial for optimal system performance. Air leaks at these connection points significantly reduce efficiency, leading to higher energy bills and discomfort. Begin by ensuring the register or grille is properly secured to its mounting location. A loose fitting can compromise the seal, negating the efforts made to connect the ductwork. Next, use appropriate sealing materials like mastic sealant to create a complete seal between the duct and the register/grille collar. Apply the sealant evenly to the collar, ensuring complete coverage around the entire perimeter before carefully inserting the duct. Avoid excessive sealant, which could restrict airflow or create an uneven seal. Properly sized ductwork is essential; using undersized ducts will lead to increased pressure and potential leakage.

After the duct is inserted, gently but firmly push it into place, ensuring a snug fit. Check for any gaps or openings where air might escape. Once you’re satisfied, allow the mastic to fully cure as per the manufacturer’s instructions before turning on the system. To further ensure an airtight seal, consider using metal clamps or other fastening methods in conjunction with sealant. These supplementary measures provide added security and prevent accidental disconnections. Regular inspections can help identify any issues over time. By following these steps carefully, you will significantly improve the overall efficiency and performance of your HVAC system.

Insulating Flex Duct for Optimal Efficiency

Proper insulation of flexible ductwork is paramount for maximizing energy efficiency and minimizing energy loss. Uninsulated ducts can lead to significant heat loss in winter and heat gain in summer, directly impacting the efficiency of your heating and cooling system. Choose insulation materials with a high R-value, a measure of thermal resistance. Common options include fiberglass duct wrap or specifically designed insulation for flexible ducts. The recommended R-value will depend on your climate and the specific requirements of your system. Always refer to local building codes and manufacturer’s recommendations for appropriate insulation levels.

Before applying insulation, ensure the ductwork is correctly installed and free of any kinks or compression that could hinder airflow. When insulating, carefully wrap the duct with the chosen material, ensuring complete coverage and avoiding any gaps or overlaps. Secure the insulation with tape specifically designed for this purpose, preventing it from shifting or detaching during operation. Avoid over-tightening the tape, as it could compress the duct and reduce airflow. Remember, proper insulation not only saves energy but also prevents condensation, which can lead to mold growth and structural damage. Insulating your flexible ductwork is a worthwhile investment that contributes to a more efficient and comfortable indoor environment.

Testing for Leaks and Airflow⁚ Ensuring Proper Function

After completing your flex duct installation, thorough testing is crucial to verify proper functionality and identify any potential issues. A system with leaks will be inefficient, wasting energy and money. Begin by visually inspecting all connections and seals for any gaps or openings. Pay close attention to areas where duct sections are joined, as these are common points of leakage. A simple test involves turning on your HVAC system and carefully feeling along the ductwork for any escaping air. You can also use a smoke pencil to visually detect air leaks; the smoke will follow the path of escaping air, revealing any weak points.

For a more comprehensive evaluation, consider using a professional-grade duct leak detection tool. These devices measure airflow and pressure to accurately pinpoint and quantify leaks. Addressing any leaks promptly is vital to optimize energy efficiency and ensure your system operates at peak performance. After resolving any leaks, test the airflow throughout the system to ensure even distribution. Inadequate airflow to certain areas may indicate blockages or other installation problems. Addressing these issues promptly will ensure the comfort and health of your indoor environment.

Troubleshooting Common Installation Problems

During flex duct installation, several issues might arise. Sagging is a common problem; insufficient support or overly long unsupported sections can cause this. To remedy sagging, add more support straps at recommended intervals, ensuring they don’t constrict airflow. Kinking, another frequent issue, restricts airflow and reduces efficiency. Avoid sharp bends during installation; use gradual curves to maintain proper airflow. Compression of the duct liner similarly reduces airflow. Ensure the duct is fully extended and not compressed during installation. Properly sized ducts are essential; using undersized ducts leads to increased pressure drop and reduced airflow.

Air leaks are a significant concern and can be detected by feeling for escaping air or using a smoke pencil. Seal all joints and connections thoroughly with appropriate sealant. If you encounter inconsistent airflow in different areas, check for blockages within the ductwork. This might be caused by debris, improperly installed connectors or crushed sections of the duct. If your system shows signs of poor performance after installation, revisit the installation steps and check for any of these issues. Consult the manufacturer’s instructions and the Air Diffusion Council guidelines for further assistance in resolving installation problems. Remember that proper installation is key to the optimal function of your HVAC system.

Maintaining Your Flex Duct System⁚ Cleaning and Inspection

Regular maintenance is crucial for optimal performance and longevity of your flex duct system. A visual inspection should be performed at least annually, checking for signs of damage, such as punctures, tears, or excessive sagging. Look for any loose connections or areas where the sealant might have failed, leading to air leaks. Pay close attention to areas with high humidity, as condensation can lead to mold growth. Check the insulation for any damage or deterioration, ensuring it remains effective in maintaining consistent temperatures. If you notice any significant issues, address them promptly to prevent further problems.

Cleaning your flex duct system is important to remove accumulated dust, debris, and allergens that can impact airflow and indoor air quality. While professional cleaning might be necessary for extensive buildup, you can perform some basic maintenance yourself. Use a soft brush or vacuum cleaner with a suitable attachment to gently remove surface dust from accessible duct sections. Avoid using harsh chemicals or abrasive materials that could damage the duct liner. Regular cleaning, coupled with periodic inspections, will keep your system running efficiently and extend its lifespan. Remember to consult the manufacturer’s recommendations for cleaning procedures and frequency to maintain optimal system performance and indoor air quality.